Let’s start with this image: you surely had a glimpse, while driving along Italian roads, of the great white giants imposing themselves on the landscape: wind turbines.

We know how important it is to protect our planet from pollution in any form.

Many steps have been taken over the years, but that’s still not enough. Alternative energy sources are being sought to that produced by burning fossil fuels. One of these is certainly wind power. It’s a renewable, clean energy that produces no greenhouse gas emissions while operating.

Also known as wind turbine blades, these incredible electro-mechanical structures capable of generating “clean” energy are closely linked to the world of steel hot forging.

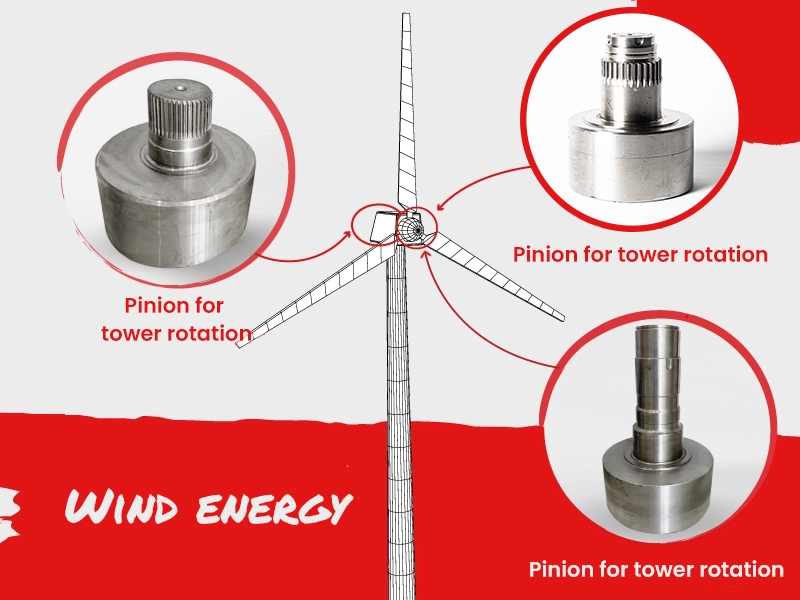

One example is pinions, which play an important role in the production of renewable energy due to their use in blade construction.

A couple of years ago I.S.A.C. started making pinions at the explicit request of Italian and foreign customers: they are intended for the construction of gearboxes that are mounted in the central hub of the blade to allow it to “seek the wind”, a bit like a sunflower seeking the sun.

Accuracy, reliability, sturdiness: this is how we build our pinions to serve the renewable energy sector, aware that even a small part like ours can play an important role in guaranteeing safety and continuity to the system it is part of; proud to be able to make a small contribution to the production of renewable energy as well as to the circular economy that is an essential characteristic of steel due to its infinite recyclability.

How does a wind turbine work? How are renewable energies contributing to CO2 reduction? What will be the next investments in marine wind farms? Go to our blog.